“What do you do for work?” The often asked ice-breaking question can be difficult for those of us in obscure or somewhat esoteric occupations. What does a steel detailer do?

The small-talk answer is something like, “I’m in construction. I do drafting for steel fabricators. Beams, columns, stairs, rails. Stuff like that.”

The response to which is invariably, “Oh, so like an Architect.”

Well, no. But yes. We do make drawings that people use to build things. But, as I like to gently rib my Architect friends and associates, “The difference between detailers and an Architect is that our drawings have to actually work out in the real world.”

I jest! But it is for this reason, that the Architect comparison rankles many detailers. Because Architects work in broader strokes on the overall design, they have the grass-is-always-greener ‘luxury’ of not having to worry about every last thing that happens inside the walls, or exactly where that HVAC duct has to come up through the roof, and so on. But it’s right there in our title: detailer. We fret over all the little details. So, what is the non-small-talk answer as to what a steel detailer does?

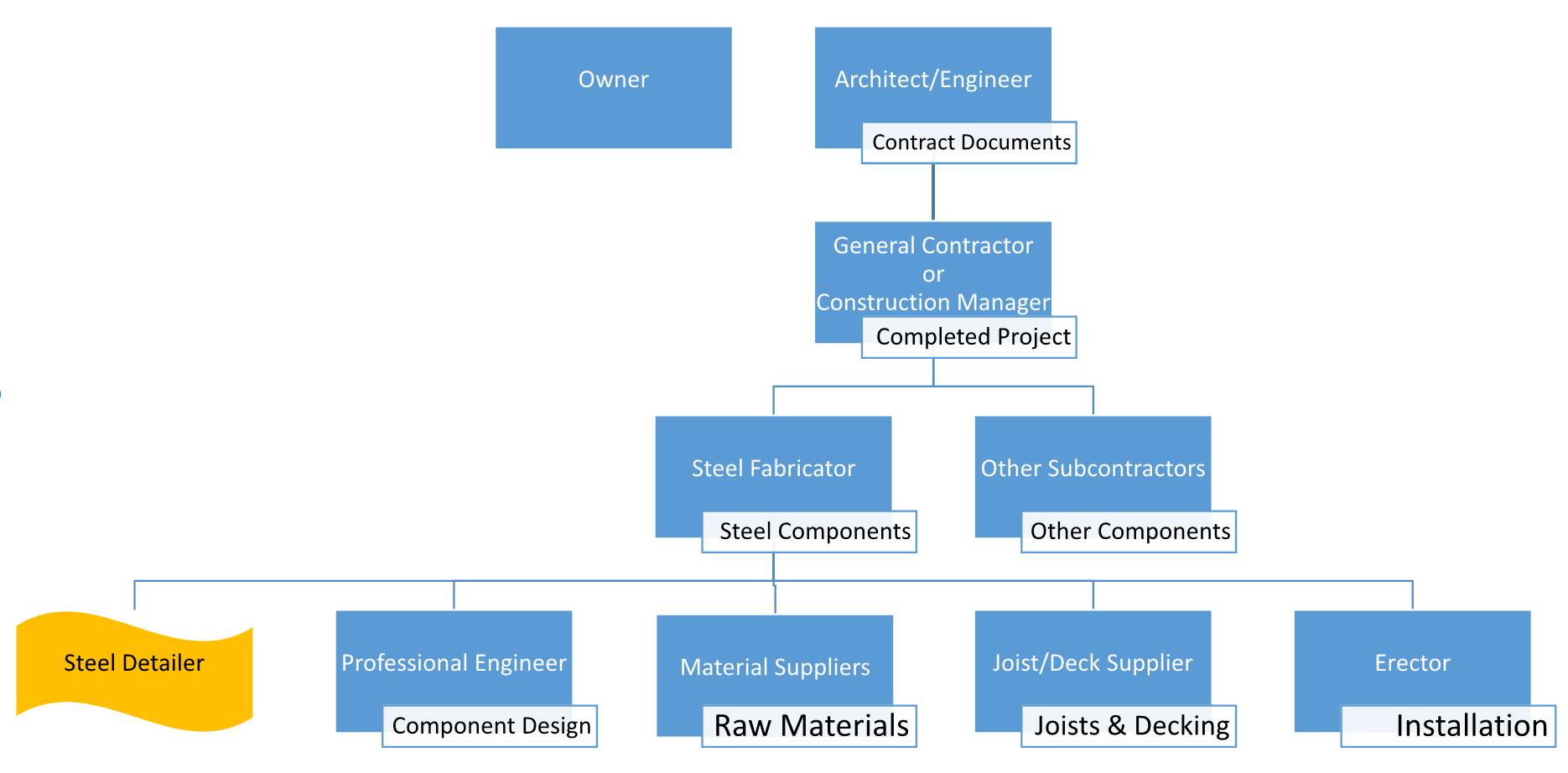

Steel detailers work, either directly as an employee, or on a sub-contract basis, for steel fabricators. Mainly, at least in the past, fabricators expect detailed shop drawings illustrating how to make each steel part required for a construction project. Each beam, each column, each diagonal brace. Stair stringers, railings. Trusses, transfer girders. Every steel outrigger, strut, hanger, spandrel, ledger, slab edge, lintel, ladder. Roof frames, door frames, sump pit frames, canopy frames. And on and on. But it’s not just a matter of generating shop drawings.

All of the steel components must meet the Architectural and Structural requirements in the construction design drawings. They must work together with each other. And they must work together with the components of other building trades. Beyond shop drawings, often the fabricator will require advance material lists for ordering raw materials, CNC and other electronic files for programming their machinery, material files for production tracking software, a BIM model for project coordination, separate sub-assembly details for making common and standard parts, bolt ordering lists, and/or bolt placement lists.

The steel detailer is also often expected to manage the RFI (Request For Information) process with the General Contractor, to resolve conflicts, get necessary information, and coordinate with other subcontractors. The detailer also works with the General Contractor and design team through the approval process, where the Architect and Engineer review and sign off on the completed shop drawings. The detailer also coordinates efforts with the fabricator’s shop personnel, Professional Engineer, material suppliers, joist and deck manufacturer, and erector to ensure it all comes together smoothly.

Essentially, steel detailing is the translation of pertinent project requirements into a format that can be used to instruct the manufacture and installation of components required under the steel fabricator’s scope of work.

And there is absolutely no room for error. Field repairs due to fabricated steel that is the wrong length, connection material welded in the wrong place, holes of the wrong size or in the wrong location, can quickly result in hundreds or thousands of dollars in additional work and materials, as well as costly schedule delays. Beyond accuracy and precision, a detailer is expected to achieve perfection.