Often in steel detailing, we need to show steel elements that connect to non-steel surfaces, such as concrete, CMU (cement blocks,) wood, or even drywall (provided that the proper blocking is provided inside the stud wall.) This article will discuss how to select and show the proper connectors on shop drawings, erection diagrams, and how to list them in bills of material or field bolt lists.

We are detailers, not Engineers. As such, we do not determine fastener diameter, length, or embed depth. If these parameters are not specified in the contract documents, the detailer may suggest a detail, but will need to flag it for verification by the responsible Engineer, either through the RFI or approval process.

Here are the most common fasteners used to connect steel to other surfaces:

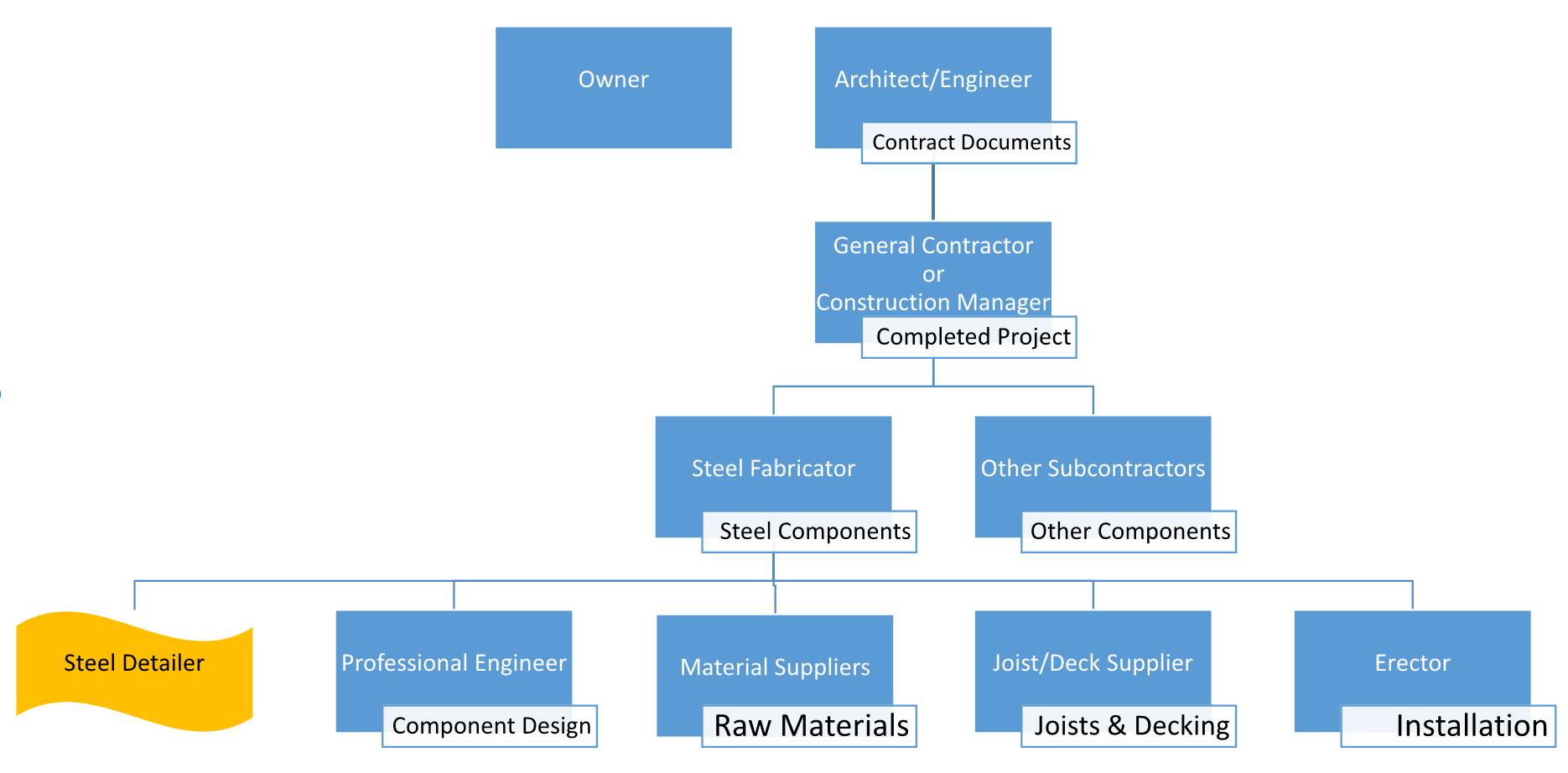

Expansion bolts or expansion anchors are a category of fastener which is inserted into a pre-drilled hole in a surface, and has a mechanism which expands when tightened. The mechanism, once tightened resists pull-out to secure the connected material to the wall or floor surface. The expansion product specs should be consulted before using to connect in an overhead surface application.

[Image: via. Click to enlarge.]

Adhesive anchors are fasteners where a pre-drilled hole in a surface is injected with an adhesive material and a threaded rod or a specialty anchor rod is inserted. Once cured, the adhesive resists pull-out to secure the connected material to the wall, floor or overhead surface.

[Image: via]

Lag screws are basically very large wood screws with a hex head.

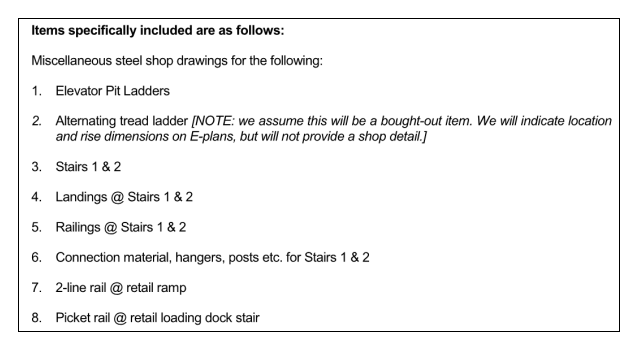

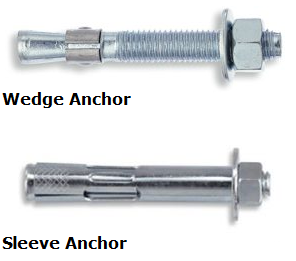

The detailer’s responsibility with these fasteners is to show and describe them with enough information that the fabricator can order the precise type and quantity of anchors required. The detailer may do this on erection diagrams, bills of material, and/or field bolt lists. In the case of adhesive anchors, a shop detail may be required if the fabricator plans to cut the threaded rods to length in their own shop.

Here is an example of an adhesive anchor detail and its shopbill information:

Note that embedment depth must be given so purchaser will know how much adhesive is required.

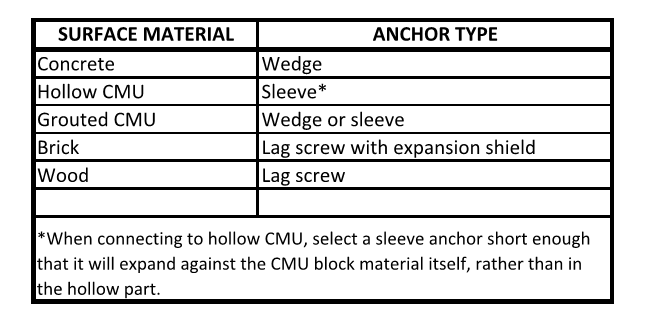

The steel detailer should also know which expansion anchors are appropriate for which situation:

Especially in misc metals detailing, the connection devices are not always specified in the contract documents. Again, we are not engineers, so selections made by the detailer need to be on the detail drawings submitted to the design team for their approval.

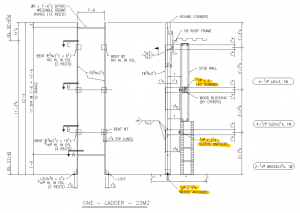

[Click to enlarge] Detail of a roof access ladder with three different types of fasteners.

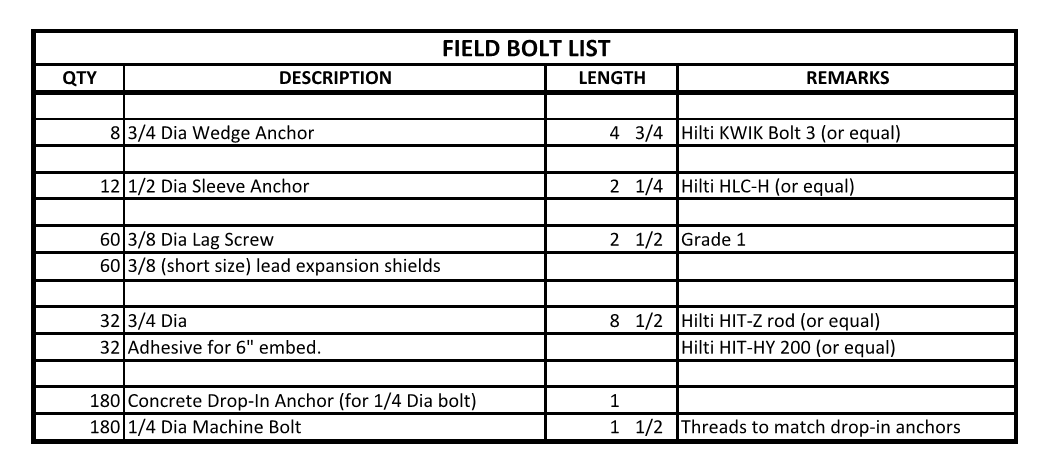

Contract documents often specify a certain brand of expansion anchor or adhesive to be used, but often the option is also given to provide an “or equal” product. In order to give the fabricator’s purchasing department the leeway to make such an “or equal” substitution, use the generic term for the fastener type on the erection and detail sheets. For instance use “wedge anchor,” instead of “Hilti KWIK Bolt 3.” However, it is important to note on the bolt list or bill of materials the specified product, so the purchaser will know what they have to match with their substitution.

Example field bolt list entries. The main thing is to include all the information necessary to order the correct fasteners.

To further make the purchasing department’s job easier, it is important to select expansion anchors in appropriate and available lengths. (They don’t come in the same 1/4″ increments as regular high strength bolts.) Consult the manufacturer’s selection to find available lengths. For example:

- Trubolt Wedge Anchors

- Kwik Bolt 3 (wedge anchors) (See page 21 of PDF)

- Dynabolt Sleeve Anchors

- HLC Sleeve Anchor (See page 4 of PDF)

*This is not a paid advertisement for Hilti or Red Head, just pointing to some useful materials.

[Image: via.]

Other types of expansion devices to mention are lead shields and drop in anchors. These devices are separate from the bolt or screw itself. They are inserted into a drilled hole, and expand either with a special tool, or when a fastener is threaded into them. These are useful in misc metal or other applications where the connection is exposed to view, and a plain bolt or screw head will give a cleaner look than a nut with threaded bolt sticking through it.

The last area of concern for the steel detailer are hole sizes in the steel to be connected with these fasteners. Unless oversized or slotted holes are specified in the contract documents, generally hole sizes will be standard 1/16″ larger than the fastener diameter. The only exception being with adhesive anchors: if the steel piece is to be used as a template to drill holes for adhesive anchors the holes will need to be oversized 3/16″ larger than the rod diameter. Again, ensure this is noted on drawings submitted for approval of the EOR. It is always a good idea to consult the fastener manufacturers’ materials to confirm hole size requirements.

The intent of this post has been to give some guidelines for detailing steel attachment devices. Requirements vary from brand to brand, and product line to product line. The internet is your friend. All of the manufacturers post tons of specifications and technical data on these products. A little research is all it takes to get it right the first time when submitting this information for approval. Project Managers and Purchasers will appreciate the effort to make their lives easier… Well, at least they won’t be cussing the detailer out when they have to track down the information themselves.